A 3 way threaded ball valve is an essential tool used for controlling flow in pipelines. It is a versatile valve that allows for diverging, converging, or mixing of the fluid within a pipeline. The valve features three ports that allow for the regulation of flow by changing the position of the valve handle.

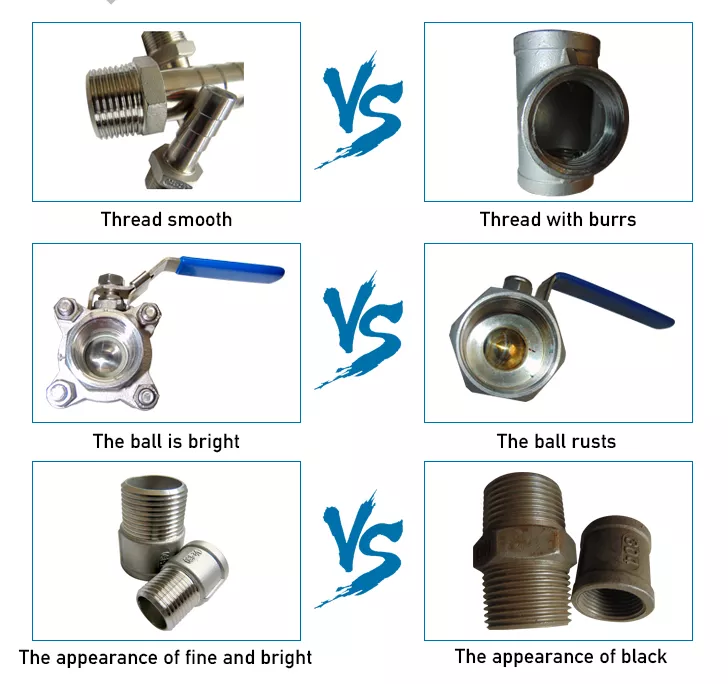

The 3 way threaded ball valve is preferred by many professionals due to its durability and accuracy in controlling flow. The valve is made from high-quality materials such as stainless steel, brass, and PVC. These materials are resistant to corrosion, wear, and tear, ensuring that the valve provides reliable service for an extended period.

One of the advantages of a 3 way threaded ball valve is its easy installation and maintenance. The valve's thread connection allows for easy attachment to a pipeline, while its design allows for easy access during maintenance. The valve's ball design ensures that there is no obstruction of flow, which reduces the risk of blockage and flow interruption.

The valve is suitable for various applications, including water treatment systems, chemical processing, and petroleum refining. It is also commonly used in industrial settings such as HVAC systems, boiler plants, and power generation facilities. With its multiple functions, the 3 way threaded ball valve is an essential tool for professionals in various industries.

In conclusion, the 3 way threaded ball valve is an indispensable tool in regulating flow in pipelines. Its unique design and durability make it a reliable valve for controlling flow in various applications. With its easy installation and maintenance, the valve provides convenience and efficiency to professionals. Overall, the 3 way thread ball valve is a top choice for controlling flow in pipelines.

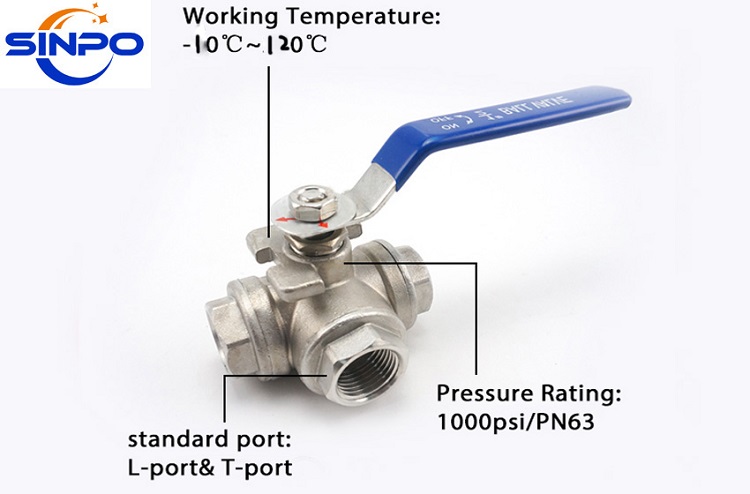

Connection | BSP, BSPT, DIN2999, NPT |

Material | Stainless Steel, WCB |

Pressure | 0 to 1000 psi |

Medium Temperature | -10 to 120℃ |

Mediums | Water, oil, air, gas, and other mediums |

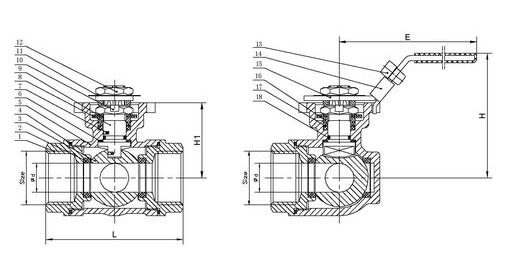

Materials

No. | Part Name | Material | No. | Part Name | Material |

1 | Bonnet | WCB, CF8, CF8M | 10 | Anti-Loose Cap | 201 |

2 | Seat | PTFE,RPTFE,PPL | 11 | Indicator | 201 |

3 | Ball | 304,316 | 12 | Nut | A194 8 |

4 | Sealing | PTFE | 13 | Pin | Plastic |

5 | Body | WCB, CF8, CF8M | 14 | Locking Device | 301 |

6 | Thrust Washer | PTFE | 15 | Handle | 304 |

7 | Anti-Static Device | 301 | 16 | Gland | 304 |

8 | Stem | 304,316 | 17 | Packing | PTFE |

9 | Washer | 301 | 18 | O-ring | FKM |

Dimensions

Size | d | L | H | H1 | E | Connection |

1/4" | 8 | 65 | 62.5 | 36 | 120 | NPT, BSPT, BSP, G, etc |

3/8" | 8 | 65 | 62.5 | 36 | 120 | |

1/2" | 12 | 68 | 62.5 | 36 | 120 | |

3/4" | 15 | 75 | 66 | 39 | 120 | |

1" | 18 | 85 | 77 | 46.5 | 160 | |

1 1/4" | 25 | 110 | 86 | 55 | 160 | |

1 1/2" | 32 | 125 | 101.5 | 64.5 | 190 | |

2" | 38 | 145 | 107.5 | 70.5 | 190 |

The product is mainly used to block, distribute and change the direction of movement of the medium in the pipeline. Any pipe can be used as inlet or outlet as required. The above are the specific specifications of the product.

Feature

1. Maximum operating presure: 1000 psi

2. Maximum operating tempresure: 120℃

3. Available size:1/4"-4"

4. Material: Steel Stainless

5. Medium: gas, oil, water

6. 100% tested