Introduction

The function of the Threaded Swing Check Valve is to control the one-way flow of the fluid to avoid the reverse flow and backflow of the fluid. The structure of this valve is relatively simple, mainly composed of the valve body, valve disc, and spring. When the fluid flows to upstream of the valve, the valve opens automatically, and the fluid can pass through smoothly; when the fluid starts to flow backward, the valve clack automatically closes to prevent the fluid from flowing back. This design makes the product very suitable in the fields of sewage systems, water supply systems, and chemical systems. The raw materials we use comply with national and industry standards, and we can provide products with different threads according to customer needs.

Advantages

High precision: We use automatic CNC machine tools to realize the efficient production of Threaded Swing Check Valves, so the product precision is very high, and the uniformity is also very high. At the same time, we will conduct pressure tests on products to eliminate unqualified products and ensure the safe and stable operation of industrial systems.

Stable and reliable: The material selection of the disc affects the quality of the valve. Usually, the temperature and pressure of the environment where the valve is located will be relatively high, which requires the material of the valve to withstand high temperature and pressure. We usually use high-temperature and high-pressure resistant materials, such as stainless steel, copper alloy, or titanium alloy to produce products. These materials have good sealing and corrosion resistance, which can ensure the effectiveness of the valve in high temperature and high-pressure environments (-29 to 300°C, 0 to 64 bar).

Ease of maintenance: The Threaded Swing Check Valve can be fixed on the pipeline by a threaded connection, and the installation process is relatively simple. There is usually an interface for loosening the nut above the valve seat, which is convenient for maintenance personnel to overhaul or replace the valve disc, and at the same time avoids the situation of disassembling the pipeline. In addition, the use of anti-rust oil can also make the product easier to store for a long time.

Type: horizontal check valve Place of Origin: Zhejiang, China Brand Name: SINPO Application: General | Temperature of Media: High Temperature, -29~300℃ Power: Manual Port Size: 1/2 to 4 inch |

10000 Piece/Pieces per Month

Packaging Details: Each product is packed into a plastic bag, then packed into inner box and carton, finally packed into plywood cases or pallets.

Port: Ningbo, Shanghai, etc

Lead Time: Most of the products are in stock, and it takes 15-25 days for products that are not in stock.

Connection | BSP, BSPT, DIN2999, NPT |

Material | Stainless Steel, WCB |

Pressure | 0 to 64 bar |

Medium Temperature | -29 to 300℃ |

Mediums | Water, oil, air, gas, and other mediums |

Materials

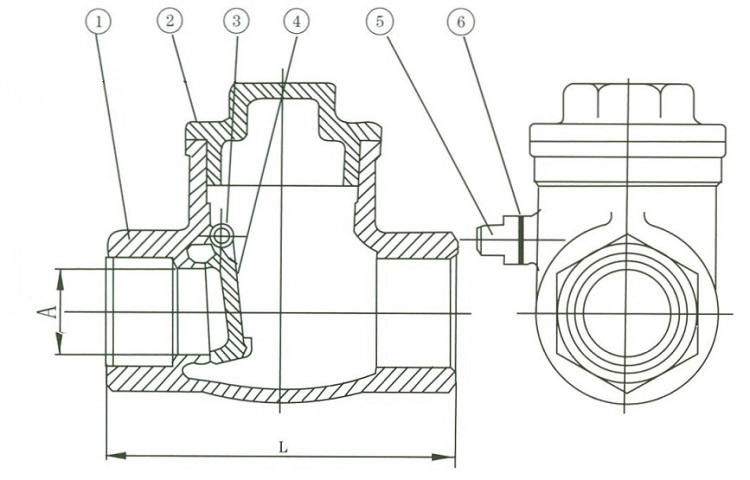

No. | Part Name | Material |

1 | Body | CF8, CF8M |

2 | Bonnet | CF8, CF8M |

3 | Pin | 304,316 |

4 | Disc | CF8, CF8M |

5 | Plug | 304 |

6 | Gasket | PTFE |

Dimensions

Size | L | A |

1/2" | 60 | 15 |

3/4" | 74 | 20 |

1" | 79 | 25 |

1 1/4" | 97 | 32 |

1 1/2" | 110 | 40 |

2" | 132 | 48 |

2 1/2" | 161 | 65 |

3" | 186 | 80 |

4" | 236 | 100 |

Why Choose Us

We are dedicated ourselves to research and develop Stainless steel flow equipment over 20 years, such as Pipe fittings, Valves and Flanges

Advanced manufacturing equipment, perfect inspection method would assure the quality of our products. Sovereignty for exporting and importing and over 20-year export experience would ensure our cooperation smooth.

Application

Petrochemical & Gas industry, chemical, machinery, electric power, papermaking, construction Water works, Shipbuilding industry, Power industry, Valve industry, and general pipes connecting projects etc.

Our company mainly produce float valves, ball valves and fittings, we have been in this field for many years, and we have our own research and development team, design team, which could help cusotmers to solve a series of problems of installing and maintaining.

Quality is priority. Our people always attach great importance to quality. Controlling from the production beginning to the end. We have well-trained and professional workers and strict QC system in each production link. And each product has to be 100% inspected before shipment.

Packaging

1. Commonly package the products by plastic bag and put it into carton,pallet or wooden cases.

2. Others packaging methods are customized.

Shipping

1. We could deliver the goods by international express, such as DHL, UPS, TNT, EMS, others.

2. You could also choose the transportation according to your schedule and budget.

3. Or you could use your own cargo agent.

1. Do you have OEM service ?

A: Yes. A variety of products size , quality and quantity can be cutomized according to your needs.

2. Could you offer a free sample ?

A: Yes, samples can be provided for free.

3. How can I pay for the products ?

A: We accept a variety of payment methods. Such as T/T , L/C,D/P ,Western Union , Paypal ,Trade Assurance.

4. How do you deal with that if there are some quality problems in products?

A: We will be responsible for all the quality problems.

5. Are you a facrory or trade company ?

A: We are a factory with 20 years experience in valve research and production .

Types of Check valves. Swing Check valve. A basic swing Check valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. ike all check valves, Swing check valves are used to avoid reverse flow in the pipe.