Type: high pressure gate valve Place of Origin: Zhejiang, China Brand Name: SINPO Application: General Temperature of Media: High Temperature, -10~300℃ | Power: Manual Body material: CF8(304) or CF8M(316) Standard: ANSI, JIS, GB, DIN Certificate: CE, RoHS, ISO9001, TUV Suitable Medium: Water, Oil, Steam, Liquid, etc |

Supply Ability

10000 Piece/Pieces per Month

Each product is packed into a plastic bag, then packed into inner box and carton, finally packed into plywood cases or pallets.

Port

Ningbo, Shanghai, etc

Lead Time

Most of the products are in stock, and it takes 15-25 days for products that are not in stock.

Introduction

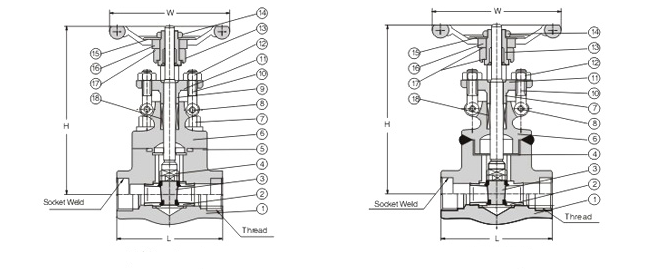

The main function of the Forged Steel Gate Valve is to control the inlet and outlet of the fluid in the pipeline, and its opening and closing can directly affect the flow of the fluid in the pipeline. During pipeline operation, if flow needs to be stopped or adjusted, our valves can be used. These valves feature quick opening and closing, and their internal design allows for a very straight-through flow path, reducing fluid resistance and pressure drop, thereby increasing the efficiency of the piping system. It is widely used in many industries, including petrochemical, paper, pharmaceutical, food, and aerospace.

Features

Good sealing: Forged Steel Gate Valve's inner film is made of metal materials such as hard alloy, which has extremely high corrosion resistance and wear resistance. It can also maintain stable performance under high temperature and high pressure (-10~300°C) and is not prone to problems such as leakage.

Easy to operate: It adopts an advanced structural design, and the valve body and valve cover are tightly fixed by bolts, which makes it very convenient to disassemble and replace the internal parts. It is easy to inspect and replace worn parts during routine maintenance and service.

Good durability: Forged Steel Gate Valve is made of materials such as forged steel or stainless steel, which makes it very resistant to compression, not easy to deform even at high temperatures, and not easily affected by vibration. We have adopted strict manufacturing standards and quality control, which play a vital role in the long-term stable operation of the piping system. Moreover, the size and shape of the valves are in compliance with international standards and have good versatility.

Connection | BSP, BSPT, DIN2999, NPT |

Material | Stainless Steel, WCB |

Pressure | 0 to 64 bar |

Medium Temperature | -10 to 300℃ |

Mediums | Water, oil, air, gas, and other mediums |

Part name | A105/F6a | F304(L)/304(L) | F316(L)316(L) |

Body | A105 | F304(L) | F316(L) |

Seat | 410 | 304(L) | 316(L) |

Wedge | F6a | F304(L) | F316(L) |

Stem | 410 | 304(L) | 316(L) |

Bonnet | A105 | F304(L) | F316(L) |

Bolt | B7 | B8(M) | B8(M) |

Pin | 410 | 304 | 304 |

Giand | 410 | 304 | 316 |

Gland Eyebolt | B7 | B8(M) | B8(M) |

Gland Flange | A105 | F304 | F304 |

Hex Nut | 2H | 8(M) | 8(M) |

Stem Nut | 410 | 410 | 410 |

Locking Nut | 35 | 35 | 35 |

Nameplate | AL | AL | AL |

Handwheel | A197 | A197 | A197 |

Lubricating | 410 | 410 | 410 |

1. The pressure self-tightening seal is adopted, and both ends of the valve body branch pipe are welded.

2. The valve seat and valve disc sealing surface are made of cobalt-based cemented carbide plasma spray welding, which has good wear resistance and scratch resistance.

3. The valve stem is treated with anti-corrosion nitriding, which has good corrosion resistance and scratch resistance.

Each of our products has been carefully produced and inspected, only passing the test can pass.

1. Package: standard export paper carton and wooden or steel pallet;

2. Shipment: by sea, by air or by express.

1. Why trust in us ?

A: 20 years in this industry. It makes us professional. Good credit in this market.

2. How can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final Inspection before shipment

3. After-sales service

A: 1 year warranty for all kinds of products

As an experienced manufacturer, you can rest assured of the quality and sales service

4. Transportation

Transported by DHL, UPS, EMS, Fedex, SF, by Air, by Sea

5. If I need different measurements or weight, could you offer OEM service?

A: Sure, we can provide OEM service, also we can make new mould for your product, attaching your name brand.