Forged steel globe valves are an essential component in the world of industrial engineering and have been used for many years to control fluid flow in pipeline systems across various industries. These valves are made of high-quality materials, ensuring their durability and reliability during prolonged usage.

One of the significant benefits of the forged steel globe valve is its ability to withstand high-pressure environments. The valve's build is designed to endure severe operational stresses, including thermal and mechanical shocks, making it an ideal choice for complex industrial processes. The forged steel material used in the valve's manufacturing enhances its resistance to corrosion, rust, and pitting, making it ideal for use in harsh environmental conditions.

Furthermore, forged steel globe valves rely on manual control to regulate fluid flow, which makes them a popular choice in applications where precise control is necessary. These valves offer excellent throttling capabilities, making them suitable for use in hydraulic and pneumatic systems. Their construction also ensures zero leakage of fluids, enhancing their safety and efficiency in the industrial setting.

In addition to their reliability and durability, forged steel globe valves also have a low pressure drop, meaning they consume less power in their operation. They are also straightforward to install, making them a go-to option for maintenance and repair.

Overall, forged steel globe valves are an integral component in industrial engineering and provide many benefits and features that make them a top choice for complex industrial processes. They are reliable, durable, and provide precise control for fluid flow, enhancing the safety and efficiency of industrial operations.

Forged steel globe valve is one of our main products - our company is widely used in water affairs, shipbuilding industry, petrochemical and natural gas industry, electric power industry, valve industry and general pipeline connection engineering, etc. Our company has many engineers and more than 100 workers who can ensure the quality and delivery time. We will do our best to support our customers.

Connection | BSP, BSPT, DIN2999, NPT |

Material | Stainless Steel, WCB |

Pressure | 0 to 64 bar |

Medium Temperature | -10 to 300℃ |

Mediums | Water, oil, air, gas, and other mediums |

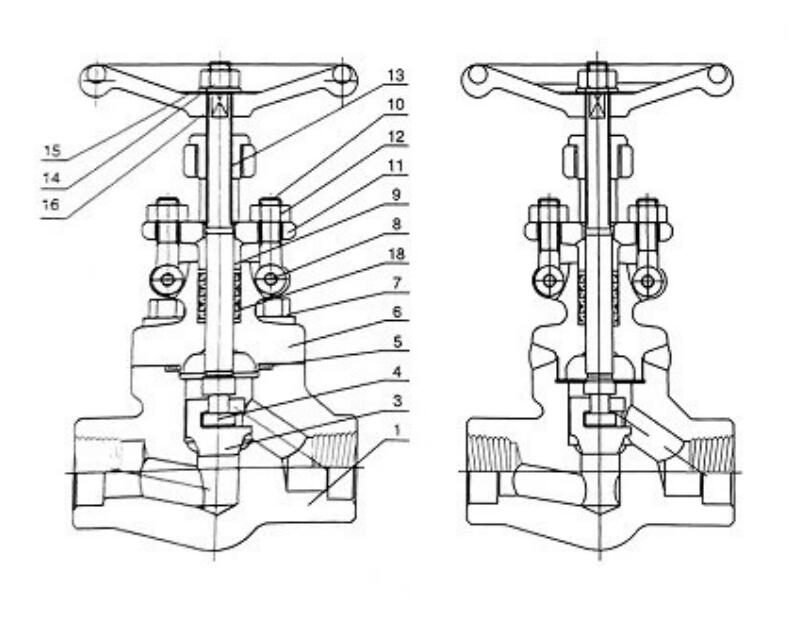

Part name | A105/F6a | F304(L)/304(L) | F316(L)316(L) |

Body | A105 | F304(L) | F316(L) |

Disc | F6a | F304(L) | F316(L) |

Stem | 410 | 304(L) | 316(L) |

Bonnet | A105 | F304(L) | F316(L) |

Bolt | B7 | B8(M) | B8(M) |

Pin | 410 | 304 | 304 |

Giand | 410 | 304 | 316 |

Gland Eyebolt | B7 | B8(M) | B8(M) |

Gland Flange | A105 | F304 | F304 |

Hex Nut | 2H | 8(M) | 8(M) |

Stem Nut | 410 | 410 | 410 |

Locking Nut | 35 | 35 | 35 |

Nameplate | AL | AL | AL |

Handwheel | A197 | A197 | A197 |

You should make a safe product selection. When selecting products, the total system design must be considered to ensure safe, trouble-free performance, function, material compatibility, adequate ratings, proper installation, operation and maintenance are the responsibilities of the system designer and user.

From quote to delivery, we can provide the detailed support you need.

1. CAD drawing

2. P&ID

3. Component selection

4. Bill of material

5. Professional services such as bending and welding

6. Testing to guarantee the system

7. Professional packaging and delivery

Feature

1. Globe valve's structure is more simple than gate valve's, and it is more convenient in manufacturing and maintenance.

2. Sealing surface is not easy to wear and scratch, and it has a good sealing surface and long service life.

3. When opening and closing, disc's route is small, so the height of globe valve is smaller than gate valve, but the length of structure is longer than gate valve's.

Our product production consists of five steps, namely roughcast casting, processing by machine, assemble, pressure test and packing.

1. Package: standard export paper carton and wooden or steel pallet;

2. Shipment: by sea, by air or by express.

1. How about your capacity?

A: As you know,we have 100staffs, own 30 CNC machines,and five person in charge of quality inspection. So please believe us we can deliver valves as you order.

2. Can you give me a discount?

A: As you know,we are manufactory,so please believe us our price is competitive. If the quantity is big,we can consider give you a discount.

3. How can I get a sample to check your quality?

A: After price confirmation, you can require for samples to check our quality. If you just need a blank sample to check the design and paper quality, we will provide you sample for free, as long as you afford the express freight.

4. If products have some quality problem,how would you deal with?

A: We will responsible for all the quality problems.

5. When can I get the price?

A: We usually quote within 3 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.