The single disc wafer check valve is a fantastic innovation in the world of fluid control systems. It is a remarkable piece of technology that is designed to ensure seamless flow control in hydraulic systems. This valve is suitable for both liquid and gas applications and has been widely used in various industries such as oil and gas, chemical, and food processing industries.

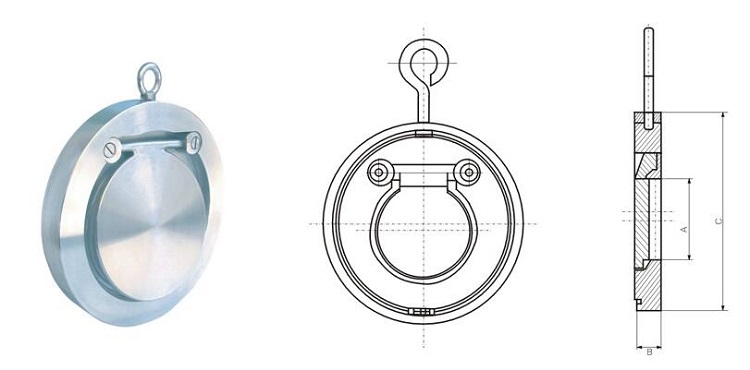

One of the key features of this valve is its simplicity in terms of construction and design. It only consists of a single disc and a spring which allows for easy installation and maintenance. The valve takes up minimal space, making it ideal for use in compact piping systems.

Another advantage of the single disc wafer check valve is that it offers a low-pressure drop. In other words, it does not cause significant resistance to fluid flow, thereby allowing for efficient use of energy. This aspect of the valve makes it highly cost-effective and economical to use in various applications.

Furthermore, the single disc wafer check valve is designed to provide excellent sealing performance. It can prevent backflow or reverse flow of the fluid, ensuring that the process flow is maintained in the forward direction. This valve performs this function without any significant leakage, which is highly beneficial in terms of safety and environmental standards.

Overall, the single disc wafer check valve is a high-performance solution that offers efficient, reliable, and safe fluid control. It is an innovation that has improved the efficiency and reliability of fluid systems in various industries. It is an extraordinary invention that is poised to revolutionize the way we control various fluids, and it represents the future of fluid control technology.

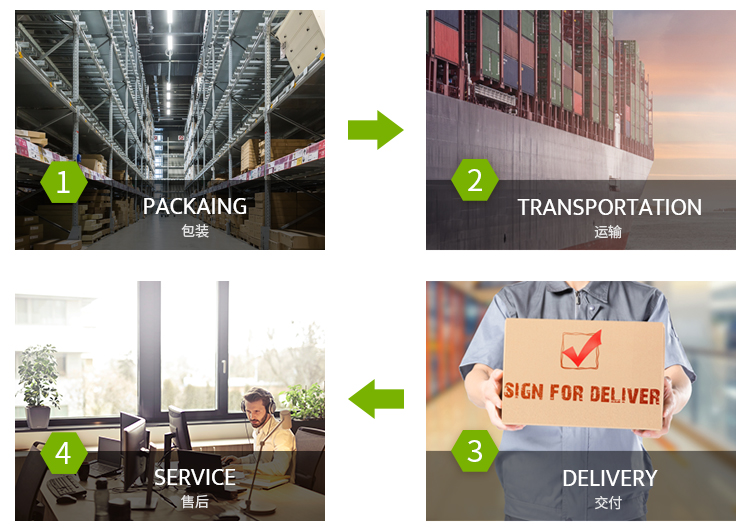

Sinpo insists on producing high-quality valves for 20 years. We have our own factory and are your reliable supplier. The Single Disc Wafer Check Valve we sell are made of high-quality raw materials, selected safe and environmentally friendly materials, and have a long service life.

Connection | Wafer end |

Material | Stainless Steel, WCB |

Pressure | 0 to 64 bar |

Medium Temperature | -29 to 300℃ |

Mediums | Water, oil, air, gas, and other mediums |

Material: WCB, CF8, CF8M, etc

Dimensions

Size | A | B | C (PN16) | C (CLASS 150) |

DN50 | 30 | 19 | 108 | 104 |

DN65 | 40 | 19 | 128 | 123 |

DN80 | 52 | 19 | 143 | 136 |

DN100 | 72 | 19 | 163 | 174 |

DN125 | 93 | 19 | 193 | 196 |

DN150 | 114 | 19 | 219 | 221 |

DN200 | 157 | 28.5 | 274 | 273 |

DN250 | 195 | 28.5 | 329 | 339 |

DN300 | 230 | 38 | 385 | 409 |

DN350 | 270 | 44.5 | 444 | 449 |

DN400 | 310 | 51 | 496 | 512 |

DN500 | 406 | 63.5 | 616 | 602 |

Factory production of single disc check valve is a slim-shaped check valve, it has the advantages of simple structure, beautiful appearance, light weight, easy to install.

The valve is mainly applied to the water supply system, petroleum,chemical, metallurgy and other industrial sectors most applicable installation space limited spaces.