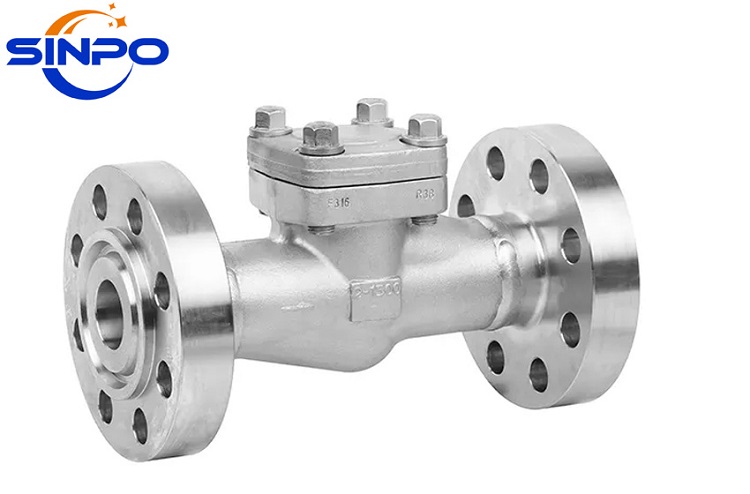

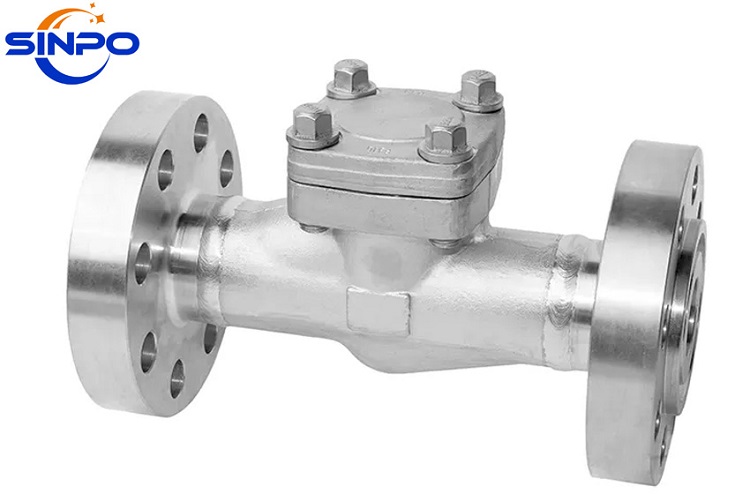

The Flanged Lift Check Valve is a crucial component in industrial machinery and infrastructure. It is designed to prevent backflow in piping systems, ensuring the smooth and uninterrupted flow of fluids and gases.

This valve is made of high-quality materials and is precisely engineered to withstand high levels of pressure and temperature. It is known for its reliability and durability, making it an ideal choice for a variety of industrial applications.

The Flanged Lift Check Valve is easy to operate and maintain, allowing for seamless integration into existing piping systems. It requires no manual intervention to function properly, and its self-acting design ensures that it operates efficiently and effectively.

Furthermore, the valve's flanged construction allows for easy installation and removal, minimizing downtime and reducing overall cost. Its compact size and lightweight design make it a practical option for various industries.

Overall, the Flanged Lift Check Valve is a valuable asset to any industrial setting. Its advanced technology and high-quality construction make it a reliable and efficient solution for backflow prevention. We recommend it without hesitation to anyone seeking a dependable check valve for their business needs.

The Flanged Lift Check Valve we produce are exquisite in workmanship and have undergone strict quality inspection. Please rest assured!

Flange Standard Options | ANSI, JIS, DIN, GB |

Connection | Flanged end |

Material | Stainless Steel, WCB |

Pressure | PN1.6~6.4MPa |

Medium Temperature | -29 to 300℃ |

Mediums | Water, oil, air, gas, and other mediums |

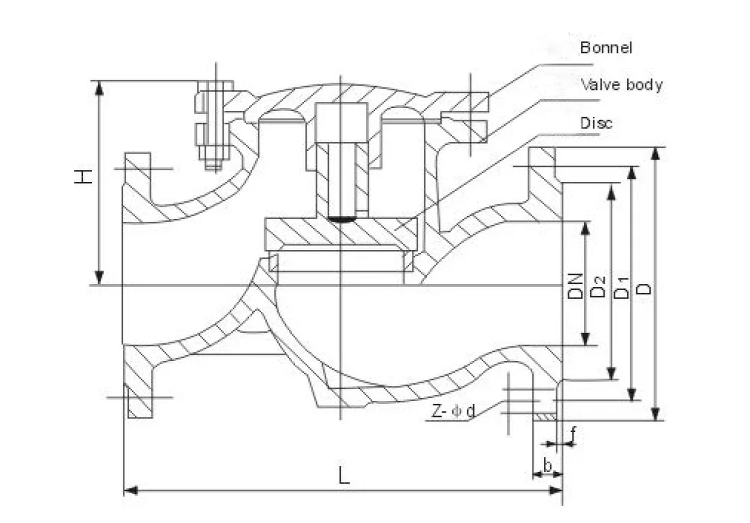

Size | L | D | D1 | D2 | b | Z-φd |

DN50 | 230 | 160 | 125 | 100 | 16 | 4-φ18 |

DN65 | 290 | 180 | 145 | 120 | 18 | 4-φ18 |

DN80 | 310 | 195 | 160 | 135 | 20 | 8-φ18 |

DN100 | 350 | 215 | 180 | 155 | 20 | 8-φ18 |

DN125 | 400 | 245 | 210 | 185 | 22 | 8-φ18 |

DN150 | 480 | 280 | 240 | 210 | 24 | 8-φ23 |

DN200 | 600 | 335 | 295 | 265 | 26 | 12-φ23 |

DN250 | 730 | 405 | 355 | 320 | 30 | 12-φ25 |

DN300 | 850 | 460 | 410 | 375 | 34 | 12-φ25 |

Size | L | D | D1 | D2 | b | Z-φd |

DN50 | 230 | 160 | 125 | 100 | 20 | 4-φ18 |

DN65 | 290 | 180 | 145 | 120 | 22 | 8-φ18 |

DN80 | 310 | 195 | 160 | 135 | 22 | 8-φ18 |

DN100 | 350 | 230 | 190 | 160 | 24 | 8-φ23 |

DN125 | 400 | 270 | 220 | 180 | 28 | 8-φ25 |

DN150 | 480 | 300 | 250 | 218 | 30 | 8-φ25 |

DN200 | 600 | 360 | 310 | 278 | 34 | 12-φ25 |

DN250 | 730 | 425 | 370 | 332 | 36 | 12-φ30 |

DN300 | 850 | 485 | 430 | 390 | 40 | 16-φ30 |

• The company aims to provide our customers with the highest quality products, the most competitive prices, on-time delivery and comprehensive warranty services.

• 20-year drive valve manufacturer, mass customization available.

• Large inventory with short lead times.

• Germany imported manufacturing equipment, 100% QC before shipment, quality is guaranteed. Industry Standard 1 Year (12 Months) Warranty.

• ISO 9001 certified, additional certifications include CE, RoHS, SGS, BV, Explosion Proof and Flame Retardant.

• Provide OEM/ODM service.

Feature

1. Corrosivity

The combination of rust and corrosion resistant stainless steel with nickel and chromium elements.

2. Strong universality:

Pipe thread and general pipeline can be replaced and installed easily,comfortable handle.

3. High quality

Stainless steel material, strong wear-resistant, good toughness, high temperature resistance, good aging durable resistance.

4. Craftsmanship

Products are under high configurational processing and strict quality inspection procedures.

5. Valves made of stainless steel, and each part can better demonstrate their function, whether it is the valve body, the main rod, or even every fixed screw, which is the same to ensure quality and safety.

Scope of application

Water, oil, steam, gas and some corrosive liquids

Quality is priority. Our people always attach great importance to quality. Controlling from the production beginning to the end. We have well-trained and professional workers and strict QC system in each production link. And each product has to be 100% inspected before shipment.

Check valves are generally installed in pipelines to prevent backflow. Foot valves are commonly used in water pumping lines to prevent water from draining in the event of a pump stop. Steam check valves or steam non-return valves are installed in pipeline systems, to enable the movement of the medium in one direction only.