The Flanged Swing Check Valve is an important component in many industrial and commercial applications. It is designed to regulate the flow of fluid and prevent backflow. Like any other mechanical device, check valves require maintenance and care to ensure optimal performance and long service life.

One of the key benefits of the Flanged Swing Check Valve is its ease of installation. It comes with flanges attached to the valve body, allowing it to be attached directly to the pipe flange. This reduces the need for additional fittings and makes installation quick and easy.

In addition to its ease of installation, the Flanged Swing Check Valve also provides reliable performance. When properly maintained, these valves can offer long-lasting service and reduce the likelihood of equipment failure and downtime. The design of the valve helps prevent fluid from flowing back and damaging downstream equipment, making it an ideal choice for critical applications.

Furthermore, the Flanged Swing Check Valve is available in a range of materials, including stainless steel, carbon steel, and ductile iron, to suit different applications and environments. This ensures that the valve can withstand harsh conditions and provide consistent performance over time.

Overall, the Flanged Swing Check Valve is a valuable component in fluid control systems. With its ease of installation, reliable performance, and adaptability to different applications and environments, it is an essential tool for many industries and businesses.

Material: WCB, CF8, CF8M, etc

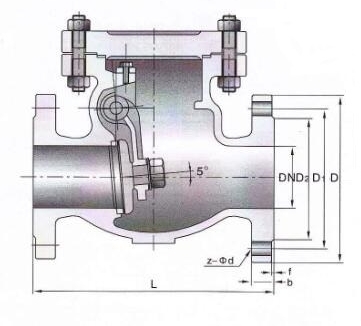

Dimensions: CLASS 300

Size | L | D | D1 | D2 | b | Z-φd |

DN50 | 267 | 165 | 127 | 92 | 23 | 8-φ19 |

DN65 | 292 | 190.5 | 150 | 105 | 26 | 8-φ22 |

DN80 | 318 | 210 | 168.5 | 127 | 29 | 8-φ22 |

DN100 | 356 | 254 | 200 | 157 | 32 | 8-φ22 |

DN125 | 400 | 279 | 235 | 186 | 35 | 8-φ22 |

DN150 | 444 | 318 | 270 | 216 | 37 | 12-φ22 |

DN200 | 533 | 381 | 330 | 270 | 42 | 12-φ25 |

DN250 | 622 | 445 | 387.5 | 324 | 48 | 16-φ29 |

DN300 | 711 | 521 | 451 | 381 | 51 | 16-φ32 |

DN350 | 838 | 584 | 514.5 | 413 | 54 | 20-φ32 |

DN400 | 864 | 648 | 571.5 | 470 | 58 | 20-φ35 |

DN450 | 978 | 711 | 629 | 533.5 | 61 | 24-φ35 |

DN500 | 1016 | 775 | 686 | 584 | 64 | 24-φ35 |

• The company aims to provide our customers with the highest quality products, the most competitive prices, on-time delivery and comprehensive warranty services.

• 20-year drive valve manufacturer, mass customization available.

• Large inventory with short lead times.

• Germany imported manufacturing equipment, 100% QC before shipment, quality is guaranteed. Industry Standard 1 Year (12 Months) Warranty.

• ISO 9001 certified, additional certifications include CE, RoHS, SGS, BV, Explosion Proof and Flame Retardant.

• Provide OEM/ODM service.

1. Swing check valve disc shapes as a disc, which is around seat channel shaft for rotary motion.

2. Its main function is to prevent medium for backflow, the pump and drive motor for reversal and container medium for relief.

3. It is suitable for low velocity and the flow doesn't often change in large diameter occasion.

Joy Valve was established in 2003, which is specialized in designing and manufacturing Stainless Steel& Carbon Steel Floating Threaded Ball Valves, Float valve, Flanged End Ball Valve, Gate Valve, Globe Valve, Check Valves and ect.With almost 20 years of production experience, we have become one of the leading manufacturers in this field.

Our company strictly complies with ISO9001:2008 system, and we have certificates CE, API, TS.We mainly produce valves according to ANSI, DIN, JIS and China GB standards.Our products are widely used in the fields of water, oil, gas, petroleum, chemical and city pipeline networks.With good quality and services, we have gained a good reputation from customers from home and abroad.

Facing the furious competition of the valve market, we will fully exert our advantages in technology and management to continously improve our product quality and manufacture high quality valves to satisfly customers.We welcome friends from home and abroad to join us, and share the markets around the world.

Production Process

Our products will be processed after initial production, and will only be shipped after strict inspection.

1. Are you trading company or manufacturer ?

A: We are factory.

2. Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

3. What's the payment terms?

A: T/T, Western Union, Credit Card and L/C etc.

4. If there is any quality problem, how do you solve it?

A: We are very proud that we never make one customer leave us. We are not 100% perfect, there is some quality problem. Normally replacement, or compensation, or resend goods to customers as per the condition. To be discussed as per condition.

5. Why trust in us ?

A: 20 years in this industry. It makes us professional. Good credit in this market.

The sewage check valve has a very simple design, allowing one-way flow and preventing the backflow of liquid to its source. Our reputation in the market is largely due to our well-engineered check valve flange type from our extensive product range.